Deep Draw Stamping D&H Industries

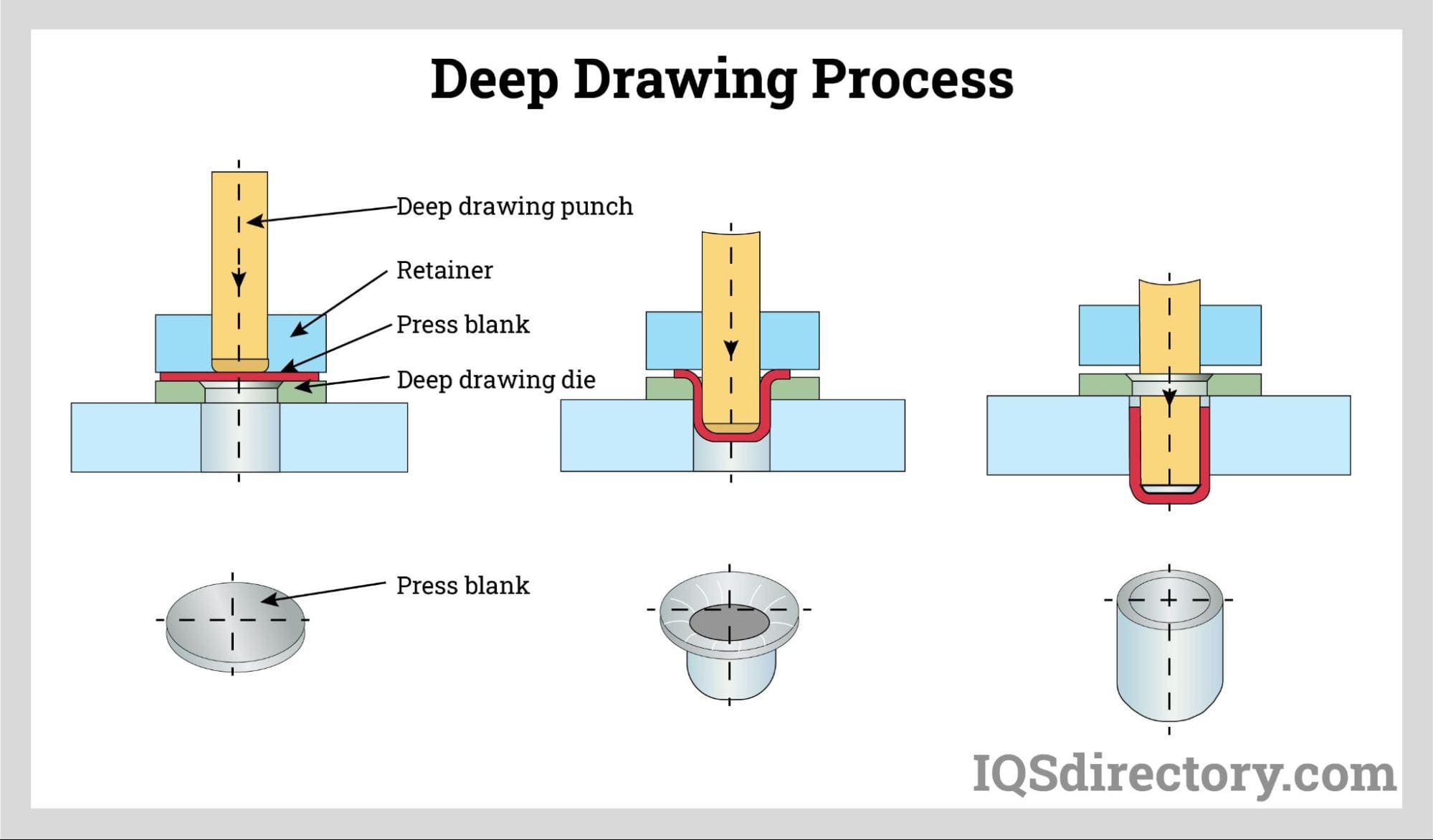

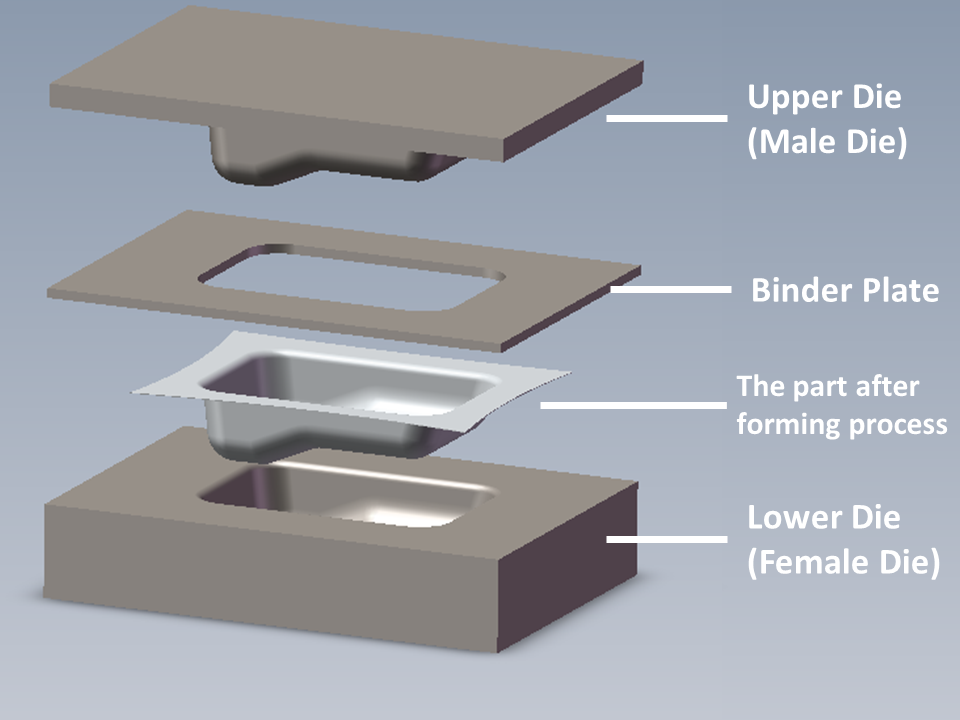

Deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. The mold for deep drawing is been called deep drawing die. Types of deep drawing parts

Deep Drawn Stamping Companies Deep Drawn Stamping Services

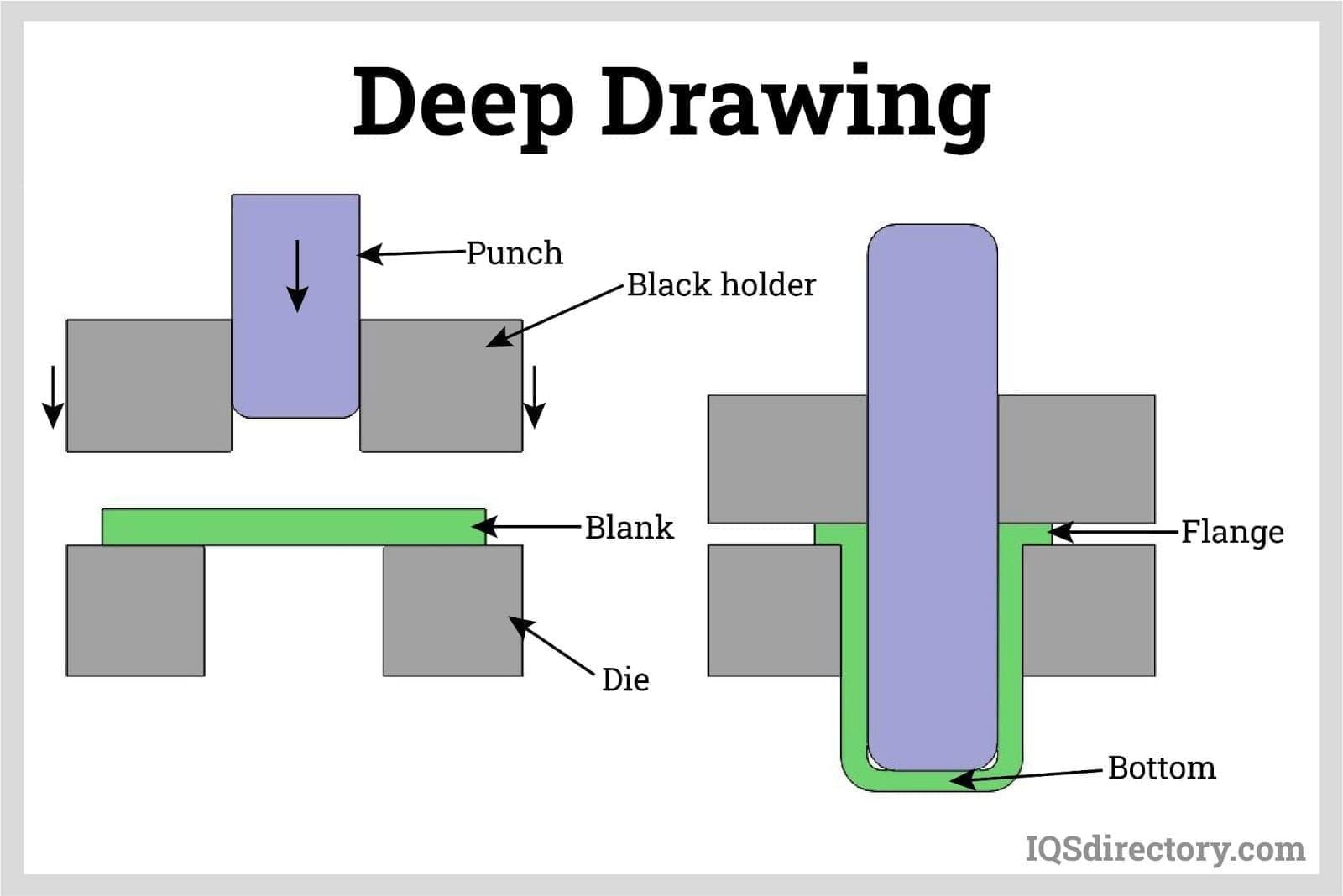

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter.

Deep Draw Part Stamping Precision Metal Stamping Resource California

For over 70 years, the talented deep draw engineers and tool makers at Prospect Machine Products have been delivering deep draw component solutions to customers worldwide on time, every time. As a small manufacturer, our tight team of experts work closely with you to solve your complex production needs and assist you with your design dimensions.

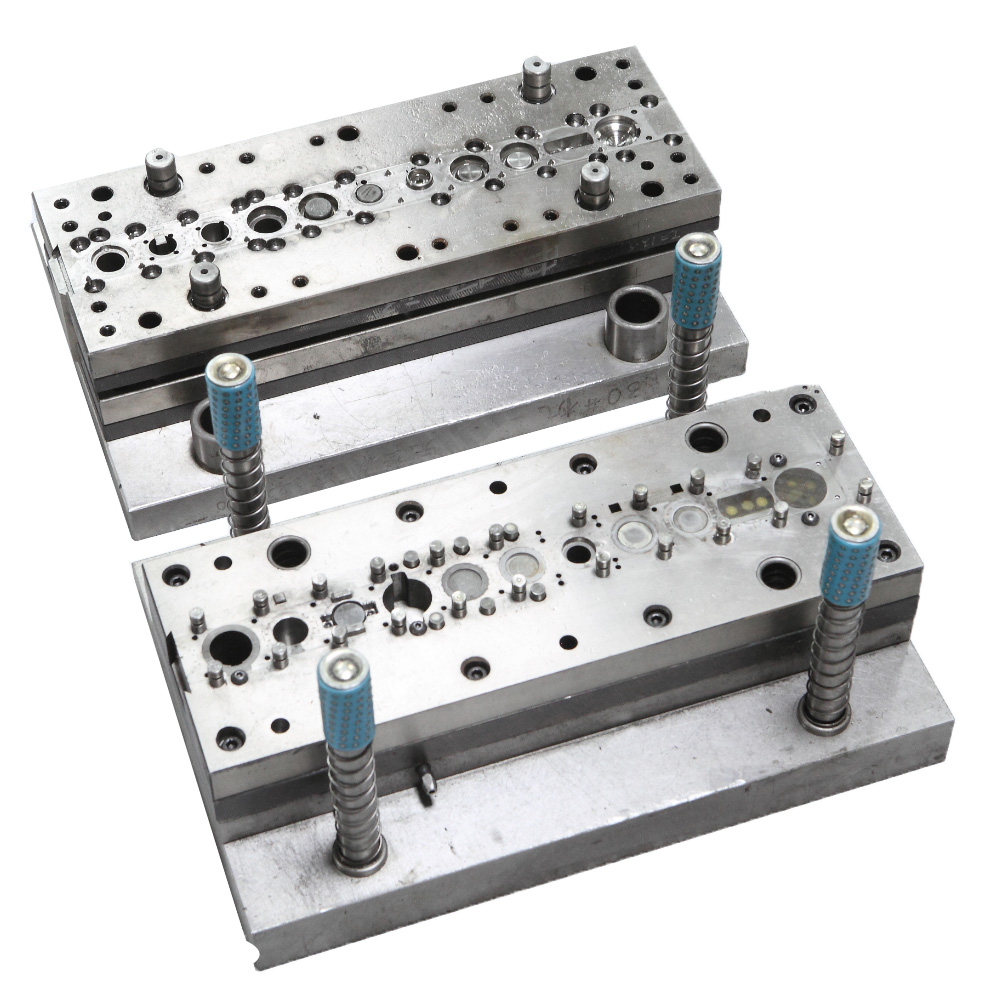

Tools for Deep Draw Metal Stampings Important Facts by PMP

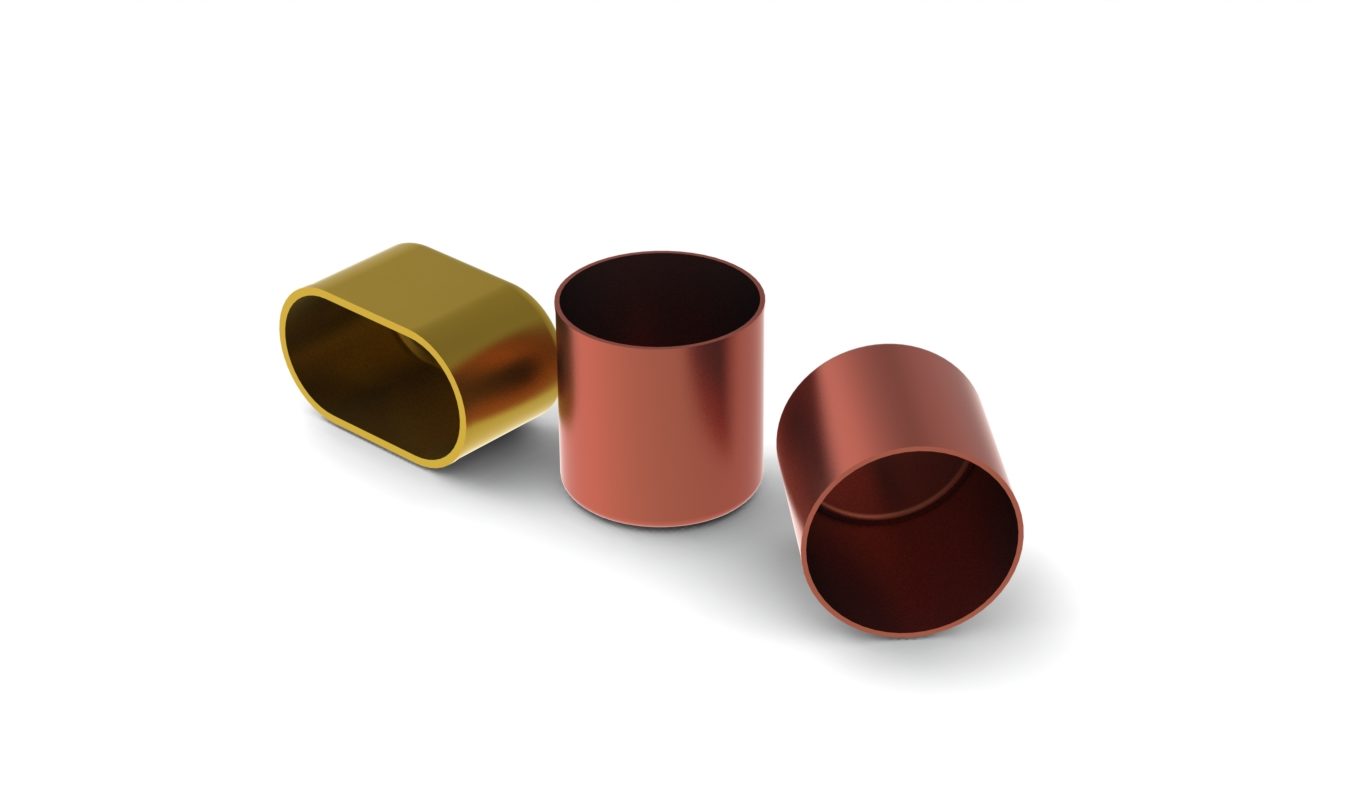

Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped cup or cylinder. It should not be confused with stretch-forming.

Deep Draw Stamping Precision Metal StampingSheet Metal Fabrication

Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions to into a cavity, producing a closed bottom, round, or irregularly shaped cup or cylinder. It should not be confused with stretch-forming.

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep draw stamping is a metal forming process that utilizes a series of dies to radially draw a sheet metal blank into a forming die by a punch, resulting in a 3-dimensional shape. This technique is especially favored for producing complex, high-precision metal parts that other methods might find challenging. Eager to delve deeper?

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep drawing - also referred to as deep drawn or deep draw stamping - is a form of metal stamping that generates seamless round enclosures (i.e., cases) that are at least as high (or taller) as they are wide. Examples of typical deep drawn components include cans, housings, and other containers.

Precision & Aerospace Metal Stamping, Pipe Caps, Deep Draw Stamping Company

Deep Drawing from A to Z. July 1, 2008. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation to understand and troubleshoot. In most forming operations, stretching or squeezing.

Deep Drawn Metal Components, Stampings, Pressings & Parts

Deep-drawn stamping is used to manufacture a diverse array of plumbing and irrigation system components because many of these parts require axisymmetric shapes that can resist leaks and withstand a wide variety of corrosion risks and weather issues. Some agricultural subcomponents built using deep-drawn stamping include:

Deep Drawn Stamping Services at Manor Tool & Manufacturing

Deep Draw Metal Stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. Cylindrical deep drawn aluminum cans are typical deep drawing applications. What are the Types of Deep Drawing Processing?

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep drawn stamping is even used to make locks, appliances, and lighting components. Deep Drawing Process. Our deep drawn stamping process allows for flat sheet metal made of various metals to be turned into shapes of three-dimensional form. The stamping presses are made up of a die and a punch. The die section is a cavity, which is in the.

Hot Stamping and Prototype Stamping Duggan Manufacturing

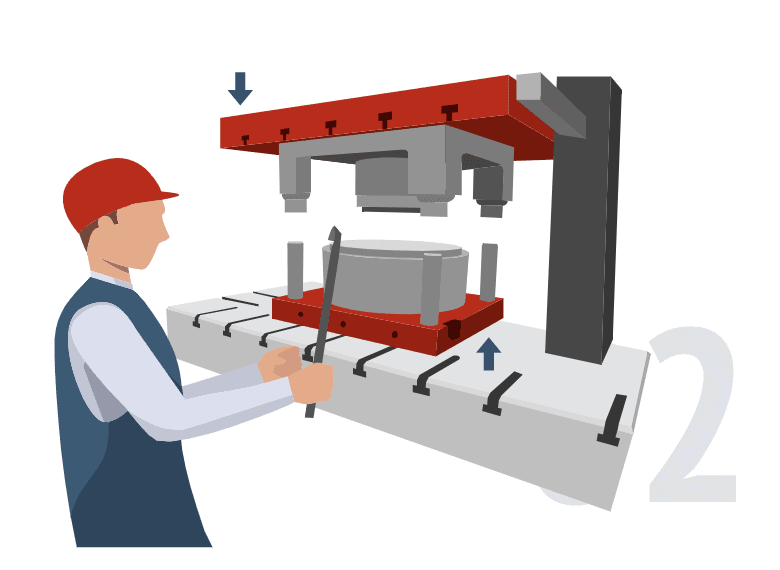

Deep Draw Process: The sheet metal, or metal blank, is placed on the die and secured. The press is then activated to force the punch against the die with up to 400 tons of force. The process is repeated until the component achieves the desired size and shape. Deep Draw Stampings Modifications

Deep Drawn Stamping Companies Deep Drawn Stamping Services

Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods.

Deep Draw Metal Stamping Getting Started

Deep draw stamping works quickly and efficiently once it has been set up, making it ideal for longer runs. · Parts that must be water- or gas-tight. The one-sheet process is seamless. · Parts that must be produced to tight tolerances. Metal stamping has high accuracy and can be set to tolerances as low as ±.0005 in.

Deep Draw Stamping Process

Step 1: Planning the Part Design. Every deep draw metal stamping process starts with planning the part design. Manufacturers such as Trans-Matic determine the required dies and punches based on the end product's size, shape, and customer specifications. During this phase, factors such as the dimensions of the part, the design complexity, and.

What to Expect from Your Deep Draw Stamping Supplier

Deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed into a deep (often complex) shape, whereby the flat sheet is "drawn in" from the edges and "sucked in" to create a deep shape that otherwise may not be possible using normal metal forming techniques.